MAINTENANCE PRODUCTS

Cat dealers offer a wide range of maintenance products aimed at protecting higher-value equipment components and system. While the use of these products make up a relatively small portion of the total operating cost (~3%)*, they play a vital role in realizing the full value from Caterpillar equipment.

Liquid Filter

- Excellent filter performance and protection during the entire filter life.

- Eliminates the possibility of leak paths.

- The Caterpillar center tube design is 30% stronger than metal cores.

- Resistance to pulsating high system pressures experienced during demanding applications.

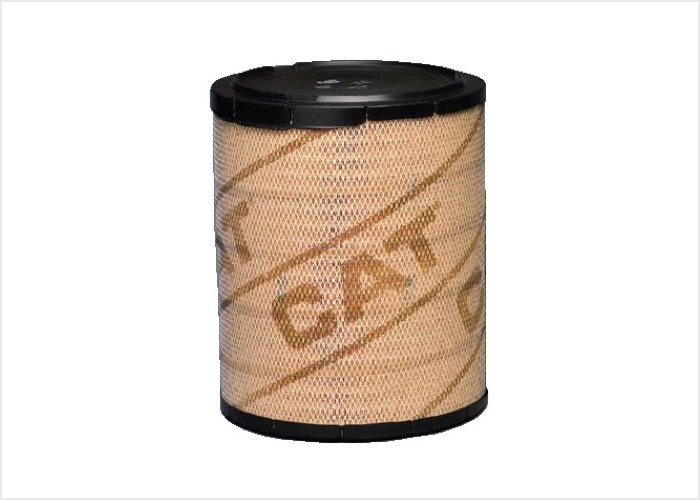

Ultra High Efficiency (UHE) Air Filter

- Less dust gets to the engine, improving fuel economy while reducing wear and maintenance costs – saving customers money.

- Cat UHE Air Filters consistently meet a high manufacturing standard for quality.

- UHE Air Filters live up to six times that of standard filters saving cost and maintenance downtime.

Engine Oil (Cat DEO-ULS™)

- Superior performance, protection and life for Cat engines.

- Enhanced protection against piston and ring groove deposits.

- Specially designed to improve the protection of both the engine and after-treatment systems.

- Improves corrosion resistance and wear protection.

- Reduces oil consumption and sludge.

- Provides excellent low temperature startability throughout the life of the oil – from fill until the next change interval.

- Helps prevent viscosity loss from shearing – a common failure characteristic of oils which significantly decreases fluid performance.

- Higher protection against thermal and oxidative breakdown.

Transmission & Drive Train Oil

- Developed, tested and approved to meet Caterpillar’s rigorous requirements.

- Protection for critical gears and bearings which require good lubricity properties.

- Allow friction disc material to last longer and perform as expected.

- Wide temperature range protection.

Hydraulic Oil

- 6000hr extended drain intervals (up to 3 times that of previous offerings) when monitored with Caterpillar S•O•SSM Services oil analysis.

- Enhanced component life within the protected systems.

- Superior emulsifiers designed to keep water accumulated within hydraulic systems in emulsion.

- Improved contamination control which ultimately helps maintain equipment uptime and reduces owning and operating costs.

- Maintains consistent wear protection at both cold and hot temperatures.

- 250% increase in total life (hrs) of oxidation stability allows for longer drain intervals.

Coolant

- High performance standard.

- Eliminates the heat generated from demanding equipment applications.

- Cat Extended Life Coolant (ELC) requires no addition of water or supplemental coolant additive.

- Cat ELC reduces engine coolant and additive costs by as much as 500% compared to conventional coolant.

- Extends the life of the coolant without requiring frequent additive maintenance.

- Extended drain interval of 6000 hours (3x that of conventional products).

- More corrosion resistance and longer engine life.

Grease

- Unique thickening agent.

- Protection lowers customer risk and saves money over the long run.

- Designed for moderate to severe applications and climates.

- Wide application range.