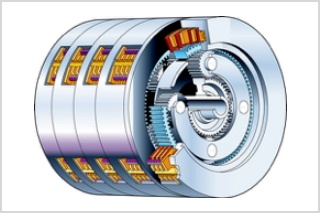

Cat dealers offer a range of drive train component repair options providing the flexibility necessary to address the many repair scenarios customers experience.

Major class component parts will have 1-year standard warranty

Order from GmmcoAssist – GO Online Order parts and manage your fleet anytime, anywhere. You can view prices, avail discounts, utilize FOC contracts, track orders and much more.

VISIT NOWConnect with our helpdesk Our support team is available to resolve all your parts related queries in your local language. Monday to Sunday: 6AM – 10PM (excluding national holidays)

Toll Free: 1800-425-2546Visit our branch Locate our branch offices and parts pick up point closest to you.

Parts Pickup locationRequest an engineer to visit Get expert advice for tailored parts and service solutions from Gmmco. You can reach us at

Toll Free: 1800-425-2546 E-Mail: sales@gmmcoindia.comReach us to get repairs done at your job site.